Plastic Injection Molding Manufacturer since 2008

LTC Plastic, a leading Chinese injection molding manufacturer located in Dongguan, specializes in high-quality molded plastic parts, delivering cost-effective, precision-engineered injection molding solutions since 2008.

One-stop Injection Molding Solutions

LTC Plastic specializes in one-stop injection molding solutions, powered by advanced precision technology and flexible production capabilities. With over 30 years of industry experience, we deliver reliable, high-quality plastic for customers around the world. Our proactive engineering support, strict quality control, and efficient production workflow enable us to turn complex ideas into fully finished parts. Today, LTC Plastic has produced thousands of customized components across packaging, automotive, industrial, and consumer goods etc.

How to Work with Us?

Have an injection molding design ready? Turning it into reality has never been easier. Upload your CAD file, receive a customized quote along with professional design advice, engineering support, low MOQ, shipment support, etc, and move seamlessly into bulk production. We ensure every part arrives on time and meets the quality you expect.

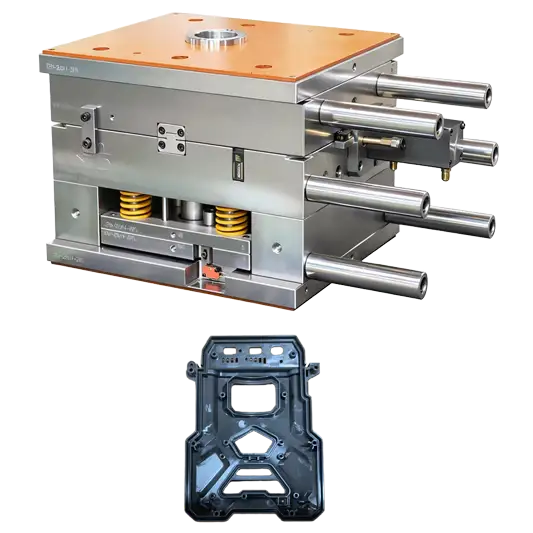

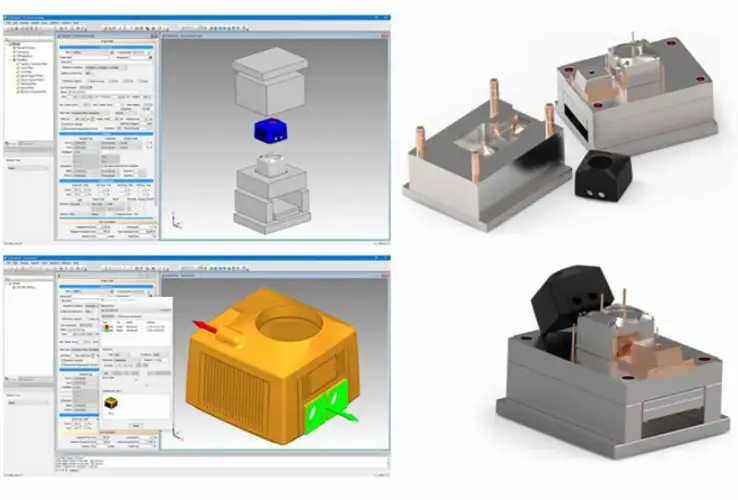

Custom mold design

To start the project, pls provide your 3D files and select the manufacturing process.

Get Quote From Us

Within a few hours, you will get our price quotation

Manufacturing

Once confirmed, we select the most suitable injection molding process and start bulk production, with customizable finishing options.

Your goods shipped

Your parts are shipped securely worldwide, and we can offer shipment support for you if needed.

Our Capacities

Our capacities include precision engineering, tooling fabrication, injection molding, CNC machining, and assembly services, as well as post-finishing. Backed by modern equipment and experienced technicians, we handle low-volume to mass production with consistent quality and fast turnaround.

Design and engineering support

- Material Selection Support

- Custom Mold Design Support

- Process Optimization

- Prototype Development

- Manufacturing Optimization

- Post-finishing support

For inquiries, please email us at keenhu@lztooling.com. We’ll get back to you within 8 hours.

- Precision Engineering

- Advanced Manufacturing Equipment

- Fast Turnaround

- Durable Tooling Materials

- Experienced Technical Team

- Flexible Customization

- Reliable Quality Control

- Cost-Effective Solutions

Comprehensive injection molding capacities

- Advanced Injection Machinery

- Strict Quality Assurance

- Efficient Production Workflow

- Flexible OEM/ODM Service

- Precision Manufacturing at Scale

- Post-finishing and assembly service

Have a custom plastic part project ?

If you have a customized plastic parts project, pls send an inquiry to us, we will follow up and provide a fast and professional solution for your project.

FAQ for injection molding

Injection molding creates parts by injecting melted plastic into a custom mold. FAQs typically cover tooling prices, minimum order quantities, suitable materials, cycle time, tolerances, and how design choices affect manufacturability, durability, and overall cost etc.

Injection Molding Support & Resources

What is your MOQ

We can support you without the MOQ issue. For low quantity orders/trials, we can offer 3D printing, CNC machining, prototype injection molding, etc.

How long I can get my Quotation

We will provide our price quotation and related feedback, concerns within 8 hours.

What industries do you serve?

We supply components for automotive, electronics, medical, industrial, construction, household goods, and consumer products.

What materials can be used for injection molding?

We work with ABS, PP, PC, PA, POM, PMMA, TPU, TPE, reinforced materials, and high-temperature resins. etc, tell us your request, and we will give our material suggestion.

What information do you need for a quote?

3D files (STEP/IGS/STL), 2D drawings with tolerances, material requirements, quantity, surface finish, and any special features etc.

How long does mold making take?

Typical mold manufacturing takes 2–5 weeks, depending on complexity, size, and part structure.

Can you help with product design or DFM?

Yes. Our engineers provide DFM analysis, optimization suggestions, and material selection support.

Do you offer prototype molding?

Yes. We offer rapid tooling and low-volume molding for testing fit, function, and market validation.

How accurate are your molded parts?

We achieve tight tolerances based on mold design, material properties, and part geometry—typically ±0.02–0.05 mm.

What types of molding processes do you offer?

Standard injection molding, overmolding, insert molding, two-shot molding, side-action molding, and complex tooling etc.

How do you ensure quality control?

Through incoming material checks, in-process inspection, dimensional tests, CMM, first-article approval, and final QC reports, etc.

What surface finishes are available?

Glossy, matte, textured, SPI polish, EDM finish, sandblasting, and customized surface patterns, etc, tell us your request and we will follow

What are your lead times for production?

After mold approval, production typically starts within 7-30 days, depending on schedule and part complexity.

Can you store and maintain molds?

Yes. We provide mold storage, maintenance, and long-term durability management for repeat production orders.

Get A Quote For Your Plastic Parts

Get a fast, accurate quote for your plastic parts by uploading your CAD files or drawings. Our engineers review your design, recommend suitable materials, and provide a clear cost breakdown if needed. Start your project with confidence and move quickly into production.

LTC Plastic, Your Injection Molding Solution Provider

Modern manufacturing demands accuracy, speed, and cost efficiency—three qualities that injection molding solutions deliver better than almost any other production method. From automotive components to medical devices, consumer electronics, industrial equipment, and packaging, companies rely on plastic injection molding solutions to create durable, reliable, and high-performing plastic parts at scale.

This comprehensive guide explores everything behind today's custom injection molding solutions, including polymer material selection, mold design, tooling development, precision molding manufacturing, process optimization, quality control, and the technologies driving next-generation production.

Whether you need high-volume injection molding, low-volume molding services, or a turnkey injection molding solution, this article will help you understand how the entire system works—and how to choose the right partner for your project.

Understanding Injection Molding Solutions

Injection molding solutions refer to the complete ecosystem of design, manufacturing, engineering, automation, and production processes used to create plastic components. A strong solution integrates:

plastic injection molding services

mold design and engineering

plastic tooling development

thermoplastic molding solutions

injection molded parts production

overmolding and insert molding

automated molding systems

Injection molding quality control

industrial molding solutions

Instead of focusing only on making a mold or producing plastic parts, a full injection molding solution ensures streamlined production, predictable quality, and scalable output.

The Injection Molding Process Explained

Today’s advanced polymer molding technology has transformed the classic process into a highly controlled, data-driven manufacturing system. A modern, optimized workflow includes:

A) Material Preparation

Thermoplastics and engineering polymers are dried, mixed, and prepared based on required performance characteristics. Many OEMs rely on engineering-grade plastic molding for strength, heat resistance, and dimensional stability.

B) Melting & Plasticizing

Granules are heated and melted in the barrel. Temperature and back pressure settings form the foundation of effective injection molding process optimization.

C) Injection Phase

Molten resin is pushed into the mold cavity at a controlled speed and pressure.

Proper setup ensures straight injection molding solutions without air traps, short shots, or burn marks.

D) Packing & Holding

Additional pressure compensates for shrinkage, ensuring full cavity fill.

E) Cooling

Cooling channels—designed using mold flow analysis services—solidify the part. This stage often represents 60% of the cycle time.

F) Ejection

Once cooled, ejector pins or automated robots remove the part.

Modern factories use injection molding automation solutions for fast, stable production.

Types of Injection Molding Solutions

Modern manufacturers require flexible, scalable systems. The most commonly used plastic production solutions include:

High-Volume Injection Molding

Optimised for millions of cycles. Ideal for automotive components, electronics housings, and packaging.

Often paired with multi-cavity mold solutions to reduce unit cost.

Low-Volume Molding Services

Suitable for pilot runs, custom components, or industries requiring frequent revisions.

These are part of injection molding solutions for small batch runs.

Rapid Injection Molding Services

Used for prototypes and accelerated product launches.

Often chosen by startups and R&D teams.

Overmolding & Insert Molding

Critical for soft-touch grips, metal-plastic integration, medical handles, and threaded inserts.

Many OEM suppliers provide insert injection molding solutions for mechanical reinforcement.

Metal Injection Molding Solutions

Used for complex metal components requiring precision, strength, and small form factors.

Injection and Blow Molding Solutions

Used for bottles, containers, medical vials, and thin-wall packaging.

Industrial Injection Molding Solutions

Focus on durability, repeatability, and long-term tooling performance for heavy-duty industries.

Automotive Injection Molding Solutions

Provide robust engineering, tight tolerances, flame-retardant materials, and strict quality systems.

Injection Molding Packaging Solutions

Designed for fast cycle times, thin-wall forming, and cost-efficient mass production.

Green Solutions in Plastic Injection Molding

Focus on energy efficiency, bioplastics, recycling, and waste reduction.

Often paired with electric machines and optimized tooling cooling systems.

Mold Design & Engineering: The Foundation of High-Quality Parts

Every successful production run starts with strong engineering. The most reliable mold makers offer:

mold design and engineering

plastic injection mold solution, and plastic injection mold solutions

cooling channel optimization

gate and runner design

parting line planning

DFM (Design for Manufacturability)

undercut analysis and side-action strategies

Advanced companies rely heavily on mold flow analysis services to forecast:

filling patterns

shrinkage behavior

warpage tendencies

venting requirements

This proactive engineering dramatically increases production stability and reduces long-term costs.

Plastic Tooling Development

Tooling is the most crucial long-term investment in the injection molding process. High-quality tooling enables:

consistent injection-molded parts production

fewer plastic injection molding defects and solutions

long service life

improved cycle time

lower maintenance and downtime

Tool steel selection (S136, H13, NAK80, P20, etc.) and machining precision determine mold accuracy and lifespan. For industrial applications, hardened steel molds are essential, especially for abrasive or high-temperature polymers.

Materials Used in Modern Injection Molding

A complete custom plastic parts manufacturing solution must consider resin performance. Common categories include:

Commodity Plastics

PP, PE, PS, and PVC—ideal for packaging, consumer goods, and daily-use items.

Engineering-Grade Plastics

ABS, PC, PA, POM, PBT—used in automotive, electronics, and mechanical components.

High-Performance Polymers

PEEK, PPS, LCP—used in aerospace, medical, and high-heat environments.

Material selection impacts:

strength

flexibility

heat resistance

dimensional accuracy

appearance

cost-effectiveness

A strong supplier provides simulation and testing to confirm performance across real-world conditions.

Injection Molding Automation Solutions

Automation has become essential for consistency and efficiency. Common automated systems include:

robotic part removal

conveyor part handling

in-mold labeling (IML)

automated gate trimming

integrated vision inspection

dryers, loaders, and dehumidifiers

smart production monitoring

Automation improves speed, consistency, and safety and supports streamlined injection molding solutions.

Injection Molding Defects and Solutions

Even the most optimized system may face production defects, but modern engineering offers reliable solutions.

Typical Defects

Warpage

Sink marks

Flow lines

Flash

Short shots

Jetting

Burn marks

Silver streaking

Static-related defects

Static with Injection Molding Solutions

Small plastic parts often accumulate static, causing dust contamination or sticking issues.

Common solutions for static with injection molding small plastic parts include:

antistatic additives

ionizing air equipment

humidity control

surface treatment

Professional partners provide full injection molding problem and solutions documentation to maintain production reliability.

Injection Molding Quality Control

A complete solution includes strict QC procedures:

First article inspection

dimensional checks

resin certification

stress tests

defect analysis

functional testing

automated optical inspection

For OEMs, strong QC is mandatory, especially for injection molding for OEM products requiring tight tolerances.

Contract Injection Molding Services

Many companies outsource production to specialized suppliers that deliver full contract injection molding services. A strong partner offers:

engineering support

tooling maintenance

stable production capacity

logistics and packaging

long-term cost benefits

This model works well for companies without in-house molding facilities.

Injection Molding Solutions for Manufacturing

In manufacturing contexts, a turnkey injection molding solution includes:

product design support

mold design and tooling

material sourcing

automated molding systems

assembly and packaging

quality documentation

international shipment

This end-to-end approach ensures predictable quality and stable delivery schedules.

Why Injection Molding Solutions Dominate Modern Manufacturing

Businesses choose injection molding because it enables:

cost-effective molding solutions

extremely fast cycle times

high consistency

support for complex geometries

multi-material or overmolded designs

tight tolerances

long-term scalability

With injection molded solutions, companies gain competitive advantages in production speed, product quality, and cost per unit.

Choosing the Right Injection Molding Solution Company

A competent partner should offer:

full engineering support

in-house tooling and machining

automation capabilities

strict quality control

global shipment options

transparent project management

experience in your industry

This ensures your plastic components perform reliably in real-world conditions.

LTC Plastic, your trusted injection molding solution provider

We, LTC Plastic, deliver reliable, precise, and cost-effective plastic manufacturing services for companies worldwide. With years of engineering expertise and a full range of plastic injection molding capabilities, we support customers from concept to mass production with confidence and efficiency. Our team specializes in custom mold design, plastic tooling development, and advanced molding technologies, ensuring every project meets the highest standards of accuracy, durability, and performance.

Whether you need high-volume production, low-volume runs, rapid prototypes, or complex overmolding and insert molding components, LTC Plastic provides tailored solutions to match your exact requirements.

Equipped with state-of-the-art automated molding systems, multi-cavity tools, and engineering-grade materials, we deliver consistent quality across millions of cycles. Our process includes detailed DFM analysis, mold flow simulation, and strict quality control to guarantee stable, repeatable results. As a customer-focused manufacturer, we prioritise transparent communication, fast response, competitive pricing, and on-time delivery.

From automotive and consumer products to industrial components and OEM assemblies, LTC Plastic is committed to being the partner you can rely on for dependable plastic production. When you need precision, speed, and long-term value, choose LTC Plastic—your trusted injection molding solution provider.

Conclusion

Modern manufacturing depends on advanced, precise, and efficient plastic injection molding solutions. Whether you need high-volume injection molding, low-volume molding services, injection molding solution companies, or a complete turnkey injection molding solution, choosing the right partner ensures faster production, better part quality, and long-term cost savings.

Today’s combination of engineering, automation, material science, and process control has transformed the industry into a powerful, scalable system capable of supporting global demand for custom plastic parts manufacturing, OEM products, consumer goods, and industrial components.